Product Category

Refrigeration Components

-

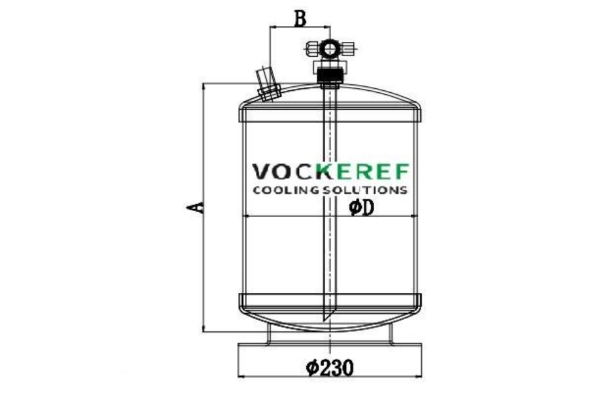

Liquid Receiver

A liquid receiver is an essential component in refrigeration and air conditioning systems. It is designed to store excess liquid refrigerant and act as a reservoir to maintain a stable system operation. Liquid receivers help to prevent liquid slugging in the compressor and ensure proper refrigerant circulation.

Advantages of Vockeref’s Liquid Receiver:

Vockeref’s liquid receiver is crafted with precision using durable materials, ensuring long service life and reliable performance. It has a large capacity to store excess refrigerant, providing stability to the system even during fluctuating operating conditions. The design of our liquid receiver is optimized for efficient heat transfer, preventing temperature buildup and ensuring proper refrigerant management. Vockeref’s product also features excellent sealing and pressure resistance, minimizing the risk of leaks and ensuring safe operation. -

Vibration Absorber

Vibration absorbers play a crucial role in reducing unwanted vibrations in various mechanical systems. They are designed to counteract and dissipate the energy generated by vibrations, thereby minimizing the negative impacts on equipment performance and longevity. Vibration absorbers are widely used in industries such as automotive, aerospace, machinery, and electronics.

These devices can be made from different materials and come in various shapes and sizes, depending on the specific application requirements. They are typically installed between the vibrating source and the structure or component that needs to be protected.

Advantages of Vockeref’s Vibration Absorber:

Vockeref’s vibration absorber is engineered with precision and high-quality materials to ensure optimal performance and durability. The advanced design of our vibration absorber effectively absorbs and dampens vibrations across a wide range of frequencies, providing excellent isolation for sensitive equipment.

Our vibration absorber is easy to install and can be customized to fit specific applications. It is designed to be compact and lightweight, making it suitable for use in space-constrained environments. -

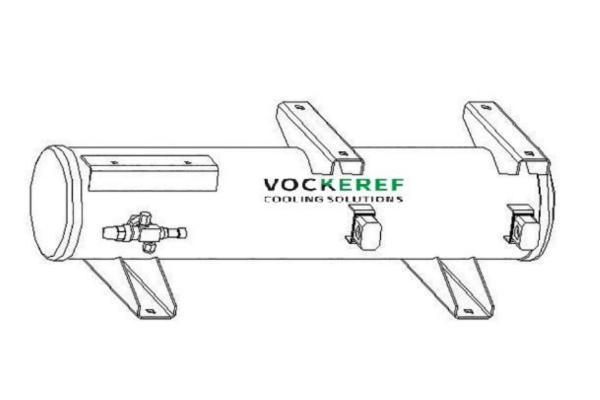

Oil Separator

An oil separator is a device designed to separate oil from a gas or liquid mixture. In various industrial applications such as refrigeration and compressed air systems, oil can mix with the working fluid and cause issues like reduced efficiency, equipment damage, and contamination. Oil separators work by utilizing physical principles such as centrifugal force, filtration, or coalescence to effectively remove oil and return it to the appropriate part of the system.

Advantages of Vockeref’s Oil Separator:

Vockeref’s oil separator is is engineered with precision to ensure maximum separation efficiency. It is made from high-quality materials that are durable and resistant to corrosion, ensuring a long service life. The design is optimized for easy installation and maintenance, saving you time and effort. Vockeref’s oil separator also has a compact size, making it suitable for a wide range of applications where space is limited. -

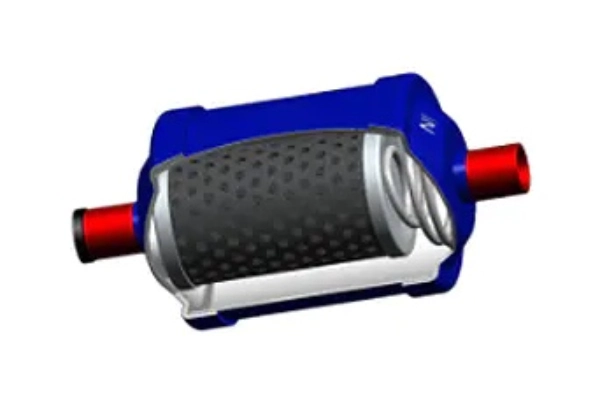

Dry Filter

A dry filter is an essential component in many systems where the removal of contaminants from a gas or liquid stream is required. It works by trapping particles, dust, and other impurities as the fluid passes through it. Dry filters are commonly used in air conditioning and refrigeration systems, as well as in industrial processes and automotive applications.

These filters come in various sizes and configurations to meet the specific needs of different applications. They can be made from different materials such as paper, fiberglass, or activated carbon, depending on the type of contaminants that need to be filtered.

Advantages of Vockeref’s Dry Filter:

Vockeref’s dry filter is crafted with precision and high-quality materials to ensure optimal filtration performance and durability. The advanced design of our dry filter effectively traps a wide range of contaminants, providing clean and pure air or fluid for your system.

Our dry filter is easy to install and replace, saving you time and effort. It is also designed to have a low pressure drop, ensuring efficient operation of your system without sacrificing performance. -

Sight Glass

A sight glass is a device used in various industrial applications to provide a visual indication of the flow or level of a fluid within a pipe or container. It allows operators to monitor the condition of the fluid, detect any abnormalities such as bubbles, impurities, or low levels, and ensure proper functioning of the system. Sight glasses are commonly found in pipelines, tanks, and processing equipment in industries like chemical, petrochemical, food and beverage, and pharmaceuticals.

Advantages of Vockeref’s Sight Glass:

Vockeref’s sight glass is made from high-quality materials that are resistant to corrosion, abrasion, and high temperatures, ensuring durability and long service life. It features a clear and unobstructed view, allowing for accurate monitoring of the fluid. The design of our sight glass is ergonomic and easy to install, reducing installation time and costs. Vockeref’s product also comes with optional features such as illumination and anti-fog coatings for enhanced visibility in different conditions. -

Solenoid Valve

A solenoid valve is an electromechanical device that controls the flow of fluid or gas. It consists of a coil of wire, a movable plunger or armature, and a valve body. When an electric current passes through the coil, it creates a magnetic field that moves the plunger, opening or closing the valve. Solenoid valves are widely used in various industries for applications such as fluid control in process systems, irrigation, HVAC, and automotive.

Advantages of Vockeref’s Solenoid Valve:

Vockeref’s solenoid valve is crafted with precision engineering and high-quality materials, ensuring durability and long service life. It offers precise control over fluid or gas flow, with quick response times and reliable operation. The design is compact and easy to install, saving space and reducing installation costs. Vockeref’s solenoid valve also features low power consumption, making it energy-efficient. -

Ball Valve

A ball valve is a type of valve that uses a spherical disc to control the flow of fluid or gas through a pipe. The ball has a hole through its center that aligns with the pipe when the valve is open, allowing the fluid to pass through. When the valve is closed, the ball is rotated so that the hole is perpendicular to the pipe, blocking the flow.

Ball valves are widely used in various industries due to their reliability, ease of operation, and versatility. They can handle a wide range of pressures and temperatures and are available in different sizes and materials to meet specific application requirements.

Advantages of Vockeref’s Ball Valve:

Vockeref’s ball valve offers several distinct advantages. Our valves are crafted with precision and high-quality materials to ensure durability and long-term performance. The smooth and precise operation of our ball valve allows for easy control of fluid flow, minimizing the risk of leaks and ensuring reliable shut-off.

Our ball valves are designed for easy installation and maintenance. They feature a simple and intuitive design that makes them user-friendly and reduces downtime. -

Check Valve

A check valve is a mechanical device that allows fluid to flow in only one direction. It is designed to prevent backflow and ensure the proper flow of liquids or gases within a system. Check valves are widely used in various industries such as plumbing, oil and gas, chemical processing, and power generation. They play a crucial role in protecting equipment and ensuring the efficiency and safety of fluid systems.

Advantages of Vockeref’s Check Valve:

Vockeref’s check valve features a streamlined design that minimizes pressure drop and maximizes flow efficiency. The valve’s tight sealing mechanism effectively prevents backflow, protecting downstream equipment and maintaining system integrity. Vockeref’s check valve is also easy to install and maintain, reducing downtime and operational costs. -

Suction Line Accumulator

The suction line accumulator is an important component in refrigeration and air conditioning systems. It is designed to collect and store any liquid refrigerant that may return to the compressor suction line. This helps protect the compressor from damage due to liquid slugging, which can occur when liquid refrigerant enters the compressor instead of vapor. Suction line accumulators play a crucial role in ensuring the smooth and efficient operation of these systems.

Advantages of Vockeref’s Suction Line Accumulator:

Vockeref’s suction line accumulator is crafted with precision using durable materials, ensuring long-lasting performance and reliability. It is designed to efficiently collect and store liquid refrigerant, minimizing the risk of compressor damage. The compact size of our accumulator makes it easy to install in a variety of systems. -

Pressure Controller

A pressure controller is an essential device in many industrial and commercial applications where maintaining a specific pressure level is crucial. It monitors and regulates the pressure of a fluid or gas within a system to ensure safe and efficient operation. Pressure controllers can be used in a wide range of industries such as HVAC, manufacturing, and process control.

These devices typically consist of a sensor that measures the pressure, a control mechanism that compares the measured pressure to a setpoint, and an actuator that adjusts the pressure as needed. Pressure controllers can be either mechanical or electronic, depending on the application requirements.

Advantages of Vockeref’s Pressure Controller:

The advanced technology used in Vockeref’s pressure controller allows for quick response times and precise adjustments, ensuring optimal system performance.

Our pressure controller is easy to install and operate, with a user-friendly interface that makes it accessible to both experienced technicians and beginners. It also features a durable construction that can withstand harsh operating conditions, providing long-term reliability. -

Oil Level Regulator

An oil level regulator is a device designed to maintain a consistent oil level in machinery and equipment. It plays a crucial role in ensuring proper lubrication and preventing damage due to insufficient or excessive oil levels. Oil level regulators are commonly used in engines, compressors, and industrial machinery.

Advantages of Vockeref’s Oil Level Regulator:

Vockeref’s oil level regulator is engineered with precision to provide accurate and reliable oil level control. The advanced design of our oil level regulator allows for easy installation and integration into existing systems. It also offers stable performance, minimizing fluctuations in oil levels and reducing the risk of equipment damage. -

Oil Gauge

An oil gauge is a device used to measure and monitor the level of oil in a reservoir or system. It provides crucial information about the oil quantity, helping to ensure proper lubrication and operation of machinery and equipment. Oil gauges come in various forms, including mechanical and digital types, and are widely used in industries such as automotive, manufacturing, and power generation.

Advantages of Vockeref’s Oil Gauge:

Vockeref’s oil gauge is crafted with precision and accuracy, providing reliable readings of oil levels. It features a durable construction that can withstand harsh environments and prolonged use. The easy-to-read display allows for quick and convenient monitoring. Additionally, Vockeref’s oil gauge is designed for easy installation and compatibility with a wide range of systems. -

Oil Filter

An oil filter is a vital component in various mechanical systems, especially in engines. Its primary function is to remove contaminants such as dirt, metal particles, and sludge from the oil circulating within the system. By doing so, it helps maintain the cleanliness and integrity of the oil, which in turn prolongs the life of the engine or machinery and ensures optimal performance.

Advantages of Vockeref’s Oil Filter:

Vockeref’s features a sophisticated filtration system that effectively traps even the smallest particles, providing superior protection for your engine. The design is optimized for maximum flow rate, ensuring that the oil can circulate freely without any restriction. Additionally, Vockeref’s oil filter is easy to install and replace, saving you time and effort. -

Expansion Valve

An expansion valve controls the flow of refrigerant from the high-pressure side to the low-pressure side of the system. The expansion valve meters the refrigerant to ensure proper cooling and efficient operation. It plays a vital role in maintaining the desired temperature and pressure levels within the system.

Advantages of Vockeref’s Expansion Valve:

Vockeref’s expansion valve features advanced technology that provides accurate and consistent refrigerant flow control, optimizing system efficiency and energy savings. The valve’s design is compact and easy to install, reducing installation time and costs. Vockeref’s expansion valve also comes with adjustable settings, allowing for customization to meet specific system requirements. -

Needle Valve

The needle valve is designed to regulate the flow of fluids or gases with a high degree of accuracy. The valve consists of a long, tapered needle that can be adjusted to control the size of the flow passage.

Needle valves are commonly found in applications where fine-tuned flow control is required, such as in laboratory settings, chemical processing plants, and oil and gas industries. They are available in different materials and sizes to meet the specific needs of different applications.

Advantages of Vockeref’s Needle Valve:

The fine-tuned control provided by Vockeref’s needle valve allows for accurate adjustment of flow rates, ensuring optimal process control.

Our needle valve is designed for easy installation and operation. It features a user-friendly design that makes it simple to adjust the flow rate and lock it in place. Additionally, Vockeref offers a wide range of needle valve options, including different materials, sizes, and end connections, to meet the diverse needs of our customers. -

Muffler

A muffler is a device designed to reduce the noise produced by an engine, exhaust system, or other mechanical equipment. It works by dampening and redirecting the sound waves generated by the flow of gases or fluids. Mufflers are commonly used in automobiles, motorcycles, industrial machinery, and power generators to minimize noise pollution and create a more pleasant environment.

Advantages of Vockeref’s Muffler:

Vockeref’s muffler is engineered with precision to provide excellent noise reduction capabilities. It is made from durable materials that can withstand the harsh conditions of various applications. The advanced design of our muffler ensures efficient sound attenuation without sacrificing performance. It also offers easy installation and compatibility with a wide range of systems. Vockeref’s muffler is designed to last, providing long-term value and reliability. -

Cold Room LED Light

Cold room LED lights are designed specifically for use in cold storage environments such as refrigerated warehouses, freezers, and cold rooms. These lights provide illumination in areas where low temperatures and high humidity levels can pose challenges for traditional lighting solutions. Cold room LED lights are energy-efficient, durable, and able to withstand the harsh conditions of cold storage facilities.

Advantages of Vockeref’s Cold Room LED Light:

Vockeref’s cold room LED light is crafted with high-quality materials that are resistant to cold, moisture, and impact. It offers exceptional brightness and uniform illumination, ensuring clear visibility in the cold room. The LED technology used in our light is highly energy-efficient, reducing electricity consumption and lowering operating costs. Additionally, Vockeref’s cold room LED light has a long lifespan, minimizing the need for frequent replacements. -

Fan Motor

Axial fans draw its name from the fact that they bow air across their axis in a linear direction. The blades of these fans force air to move parallel to the shaft about which the blades rotate. These types of fans find its applications in a wide variety of mechanical and electrical gadgets. Sizes of these fans can range from a small cooling fan for electronics to a giant fan used in wind tunnels.

Wide selection of models, dimensions and air performance levels

Optimum efficiency and noise level due to well-engineered aerodynamic design of the fan blades

Ventilation, air-conditioning and refrigeration technology, wind power and mechanical engineering/finishing equipment industry

Our axial fans prove their reputation as space saving, by moving air for hot or cold air exchange in a wide variety of devices and systems.With an increase in clock speed and power consumption of processors, graphic cards, RAM, and other computer components, there has also been an upsurge in heat production in the systems due to the normal functioning of these devices. However, these components are required to be kept under a specified temperature level to prevent overheating and leading to malfunction, and damage to systems. Fans are installed inside these modern, high-speed components for active cooling purpose. Axial-flow fan is used to remove heated air away from the components and to draw cooler air over them, thereby saving computers and its components from any damage.